Tartana Copper Sulphate Pentahydrate Project

The Tartana Copper Sulphate Project is located on the Tartana mining leases, located approximately 150 km west of Cairns and 40 km northwest of Chillagoe along the Burke Development Road (see below).

Our Mining Leases contain a heap leach – solvent extraction – crystallisation plant which produced copper sulphate pentahydrate for approximately a decade before being placed in care and maintenance in 2014. The Company has refurbished this plant during 2022 - 2023 period and commissioned the plant in late 2023. Production commenced at the end of the 2023/24 wet season and we produced our first saleable shipment in May 2024. Production has continued to ramp up with our largest shipment (150 tonnes) to-date sold at the end of August 2024.

Copper is currently being sourced from copper in solution in the ponds and residual copper in the heap leach pads. Our plan is to re-open the open pit in 2025 with copper being sourced from oxide and transition resources already identified on the Tartana mining tenements.

Our plant is complex and historically produced high quality copper sulphate pentahydrate which was utilised in agricultural stock feed markets in Australia and southeast Asia as well as supplying a technical grade product for northern Australia mining operations. The mining operations use copper sulphate pentahydrate as an activator for sphalerite (zinc sulphide) and pyrite in base metal ore flotation in concentrators and is one of the key reagents used in this process. There are major base metal mines in northern Australia including Mt Isa – Hilton, Century, Macarthur River, Cannington and Dugald River.

Copper sulphate Pentahydrate Market

Copper sulphate Pentahydrate is sold to both mining operations and into the stockfeed industry depending on the specifications of the product. The annual demand in Australia is approximately 35,000 tonnes per annum with the northern Australia mining sector dominating consumption.

Copper Sulphate Pentahydrate contains approximately 25% copper with the price based on the LME copper price per tonne (adjusted for the actual copper content i.e., 25%) plus a premium. The premium depends on the quality of the product and the market where the product is being sold.

This means our revenue is leveraged to changes in the LME copper price and we receive the full value of our copper contained in the copper sulphate pentahydrate.

Copper sulphate pentahydrate shipment leaving the Tartana Mine Site.

Plant Flowsheet

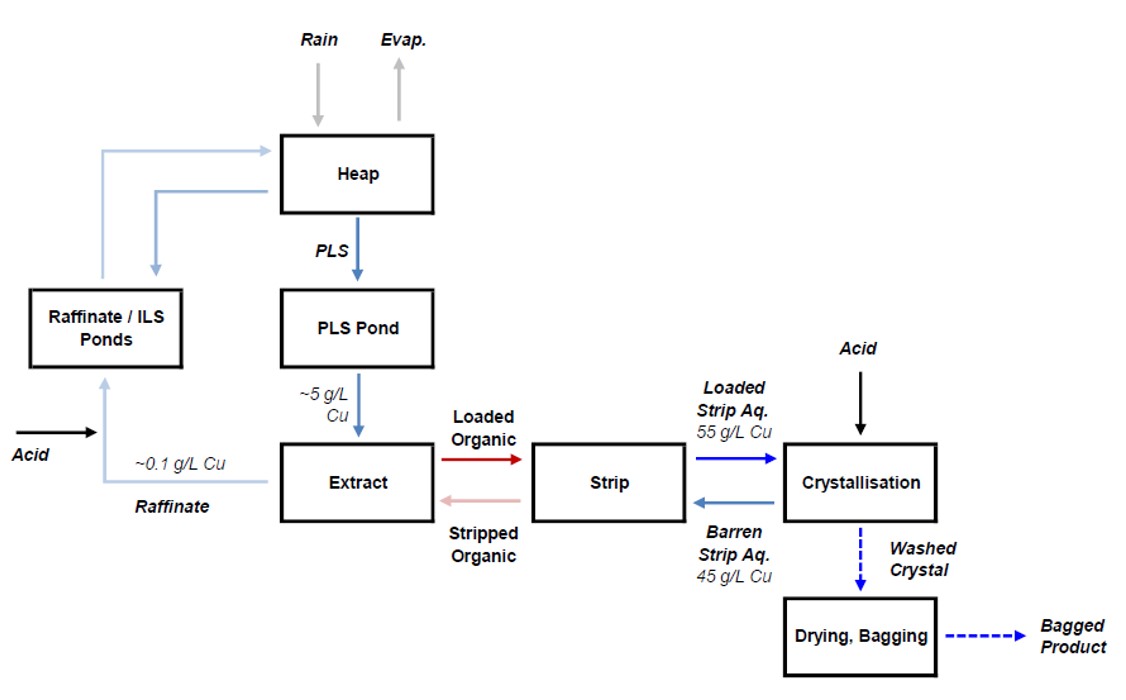

The following diagram depicts the simplified flow sheet. While the process is relatively straightforward, our inhouse expertise is directed towards the ability to purify the liquors and produce a high quality, free flowing and consistent product.

Process flow sheet

Process flow sheet

Sprinklers operating on the lower heap. Note presence of copper (blue).

Sprinklers operating on the lower heap. Note presence of copper (blue).

Plant Refurbishment

Plant refurbishment is completed and involved the replacement and upgrading of several key items including tanks, pumps and electrical control panels. The refurbishment was managed inhouse and occurred during a difficult time when the impact of Covid 19 delayed the sourcing of several components.

Relaying of the pad and bunding for acid storage.

Relaying of the pad and bunding for acid storage.

First shipment awaiting collection April 2024.

First shipment awaiting collection April 2024.

Installation of a new control panel for the generators.

Installation of a new control panel for the generators.

Installation of the dryer

Installation of the dryer

Process pond sampling

Process pond sampling