Tartana Copper and Zinc Projects

The Tartana copper/zinc project is on the Tartana mining leases which are located approximately 150 km west of Cairns and 40 km northwest of Chillagoe along the Burke Development Road (see below).

The project area lies within the prospective northwest trending Chillagoe Formation belt within the Palmerville Fault zone. The Palmerville fault is interpreted as a low angle thrust dipping shallowly northeast under the Chillagoe Formation sediments. The sediments in the hanging wall are considered to be a package of shallow to deep water sediments thrust together and separated by listric faults arising in the Palmerville Thrust. This zone hosts major porphyry and skarn related deposits including the Red Dome porphyry copper-gold skarn, the Mungana porphyry copper-gold-zinc-lead deposit, the King Vol high grade zinc skarn deposit and numerous smaller deposits along the belt.

The Company has estimate copper resources on the Tartana open pit copper and northern oxide zone and which is interpreted to represent the upper portions of a structurally controlled porphyry copper mineralisation. Separately the Company has estimated zinc resources on the Queen Grade zinc skarn. The Queen Grade zinc skarn mineralisation is similar to nearby King Vol zinc mineralisation and both may be associated with the Tartana porphyry copper mineralisation.

Copper mineralisation within the open pit and the northern zone

There has been more than 152 holes drilled on the Tartana mining leases over the last three decades with a focus on exploration for copper, zinc and gold mineralisation.

Drilling for copper mineralisation has tended focus on the Tartana open pit environs with coverage from more than 68 holes drilled into the copper mineralisation along the strike of the open pit and beyond.

Oxide copper mineralisation is close to surface and represents the upper portions of copper sulphide mineralisation at depth. The oxide copper mineralisation is targeted for leaching to recover copper for the copper sulphate pentahydrate production.

Copper Resource Estimates (MRE)

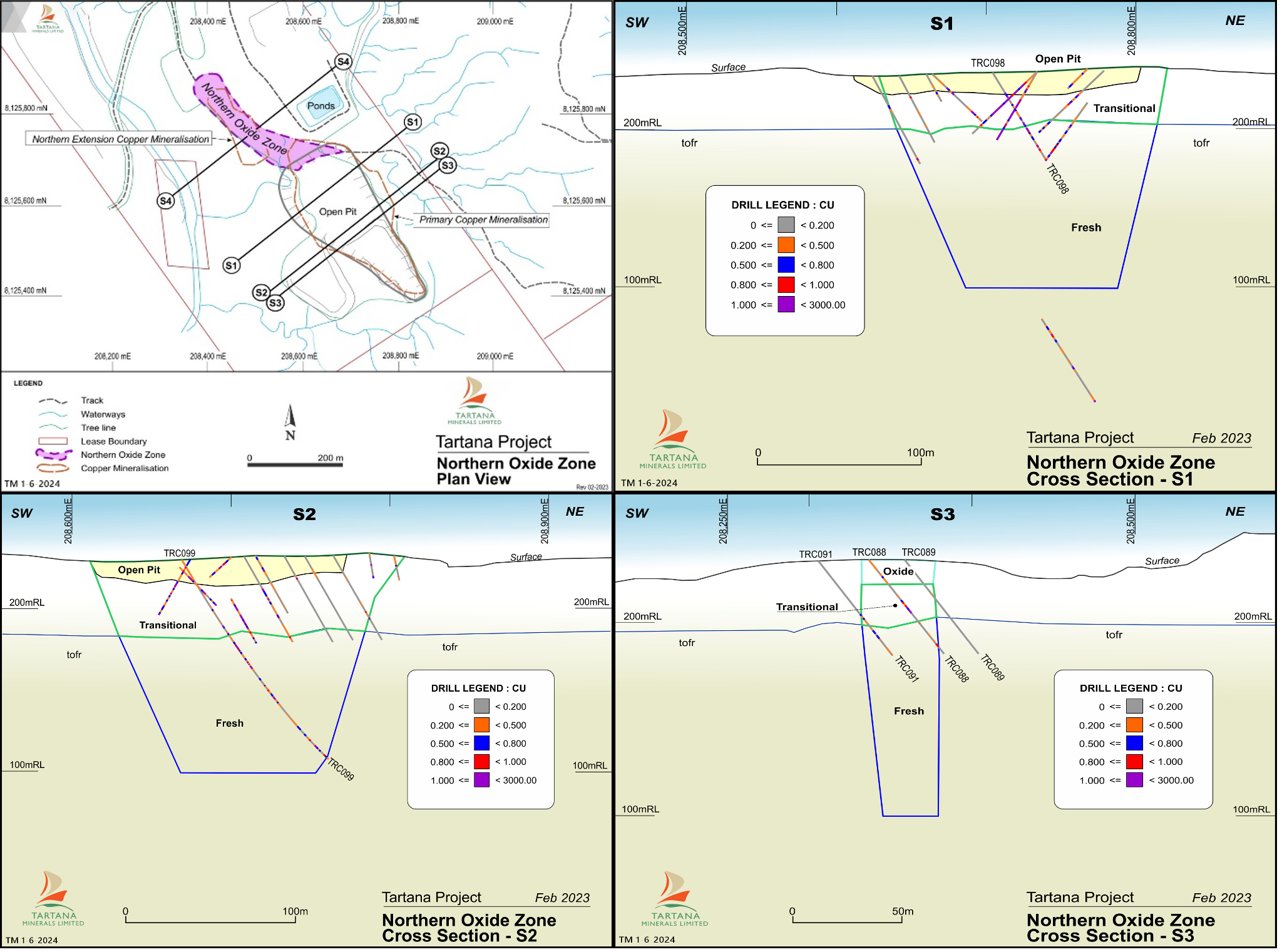

BMS Pty Ltd has estimated a copper resource which includes copper mineralisation in the base of the open pit and in the northern oxide zone. The northern oxide zone is an area where primary, transitional and oxide mineralisation continues north from the open pit but appears displaced to the west by a fault – a structure which may be important in the mineralisation event.

The resource has been estimated to a depth of 130 m but remains open below this depth and in several other directions. In 2021 the Company drilled RDD002 which was a deep hole testing an easterly IP target but also ‘clipped’ copper the mineralisation near the edge of the mineralisation below the open pit before the hole deviated down bedding and was terminated (See ASX announcement dated 28 January 2022). It unfortunately only tested a small portion of the mineralised sequence at 450 m depth having only just intersected 2 m @ 1.66% Cu, 32.6 g/t Ag and 106 ppm Bi prior to the hole being terminated.

The copper mineralisation is relatively simple with chalcopyrite – pyrite mineralisation in stockwork veins and along bedding planes in a steeply dipping shale and arkosic sandstone host rock. Alteration is dominated by sericite alteration with chlorite alteration in some areas.

BMS Pty Ltd (“BMS”) estimated an increase in Tartana copper resources based on the Northern Oxide and Tartana in pit drilling programmes conducted in the September – November period in 2022. The MRE was reported to the ASX on the 9th February 2023.

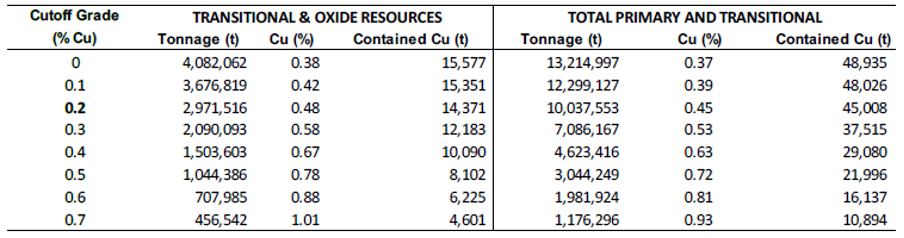

The resource grade and tonnage for the total primary and transitional ore at different cut-off grades is presented in Table 2. Recent metallurgical testwork on mineralisation below the pit has identified that most of the transitional ore is predominantly primary ore. In the northern oxide zone, metallurgical testwork is required to test the oxide mineralisation to determine the proportion of oxide copper minerals within this zone.

Table 2. Transition and primary resources at different cut-off grades. (see ASX announcement dated 9th February 2023).

Figure 3. 3(a) Mineralisation outline at surface and position of section lines, outline of historical open pit and other infrastructure. 3(b & c) Sections through the historical open pit. 3(d) Section through the northern oxide zone.

Figure 3. 3(a) Mineralisation outline at surface and position of section lines, outline of historical open pit and other infrastructure. 3(b & c) Sections through the historical open pit. 3(d) Section through the northern oxide zone.

Figure 4. Section S3 showing drilling and the block model used in the mineral resource estimation.

Figure 4. Section S3 showing drilling and the block model used in the mineral resource estimation.

Queen Grade Zinc Project

Within the Tartana mining leases the Queen Grade zinc project occurs on a parallel ridge to the King Vol zinc mine which is 800 metres further west and which is owned by Aurora Resources. The zinc mineralisation is interpreted as skarn mineralisation related to potential copper porphyry mineralisation nearby at depth.

The Queen Grade project is marked at surface by at least three significant gossanous brecciated lenses within silicified siltstone that are parallel to bedding and dip steeply southwest. The gossans are surrounded by silica–sericite alteration of the host rock, which results in a prominent northwest striking ridge. A limestone unit, which is silicified at the contact with the siltstone, is located immediately to the southwest. The silica–sericite alteration extends over a strike length of 1.9 km through ML 4820 and ML 5312. The gossanous breccia outcrops have strike lengths of 30–100 m.

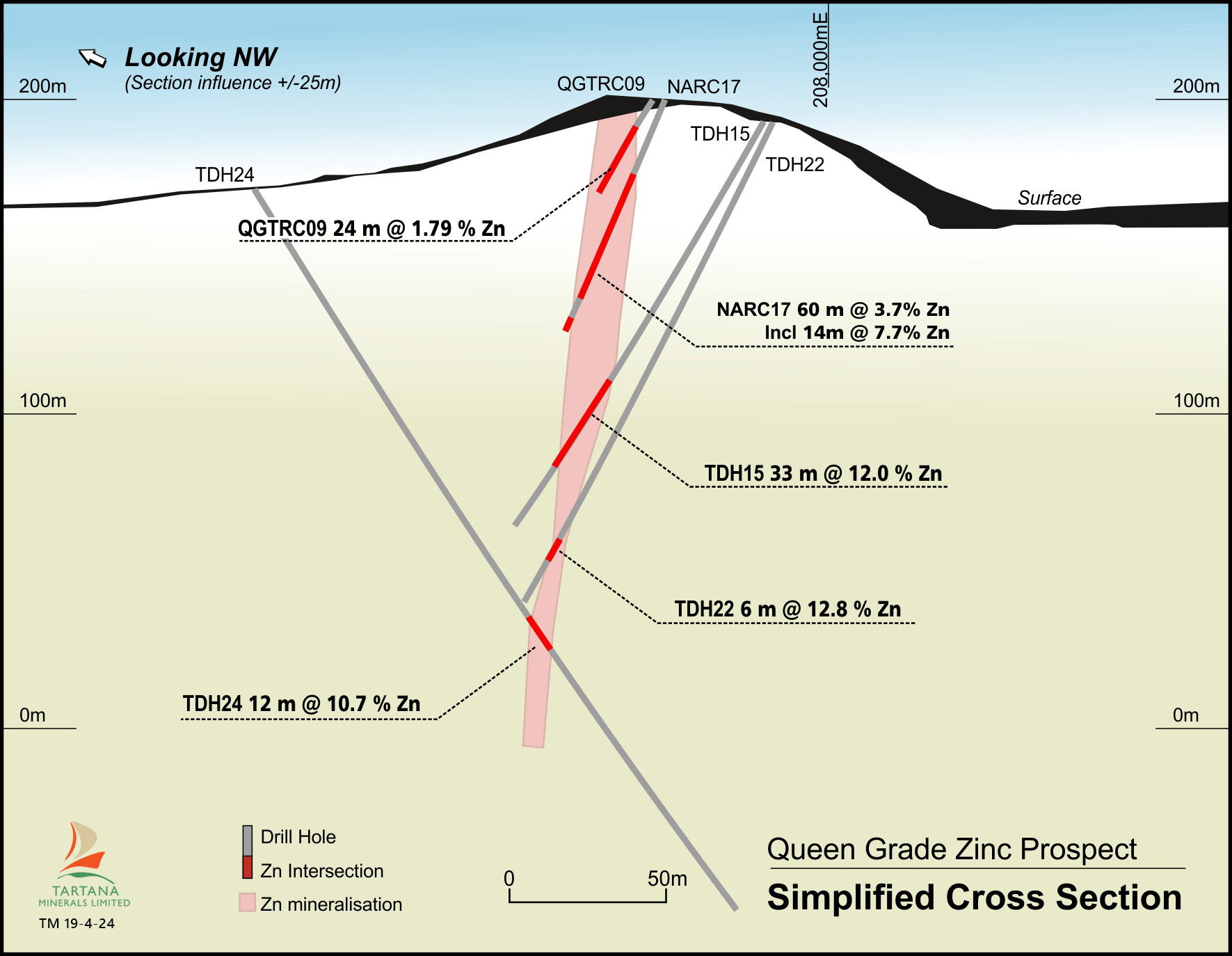

There have been a several drilling programmes conducted by various explorers in the past with highlights including:

- TDH 15 - 33m @ 12 % Zn

- TDH 22 - 6m @ 12.8% Zn

- NARC 17 - 60m @ 3.7% Zn including 14m @ 7.7% Zn

Previous deepest drillhole intersection is only 130m below surface compared to King Vol mineralisation which extends to over 900m.

Mineral Resource Estimate (MRE)

BMS has estimated the following inferred mineral resource for the Queen Grade zinc deposit at various zinc cutoff grades. The contained zinc is not overly sensitive to changes in the zinc cutoff grade reflective the massive and banded sulphide nature of the mineralisation.

Figure 1. Inferred Mineral Resources at various zinc cut off grades. Source: BMS. (see ASX announcement dated 14 February 2023).

Figure 1. Inferred Mineral Resources at various zinc cut off grades. Source: BMS. (see ASX announcement dated 14 February 2023).

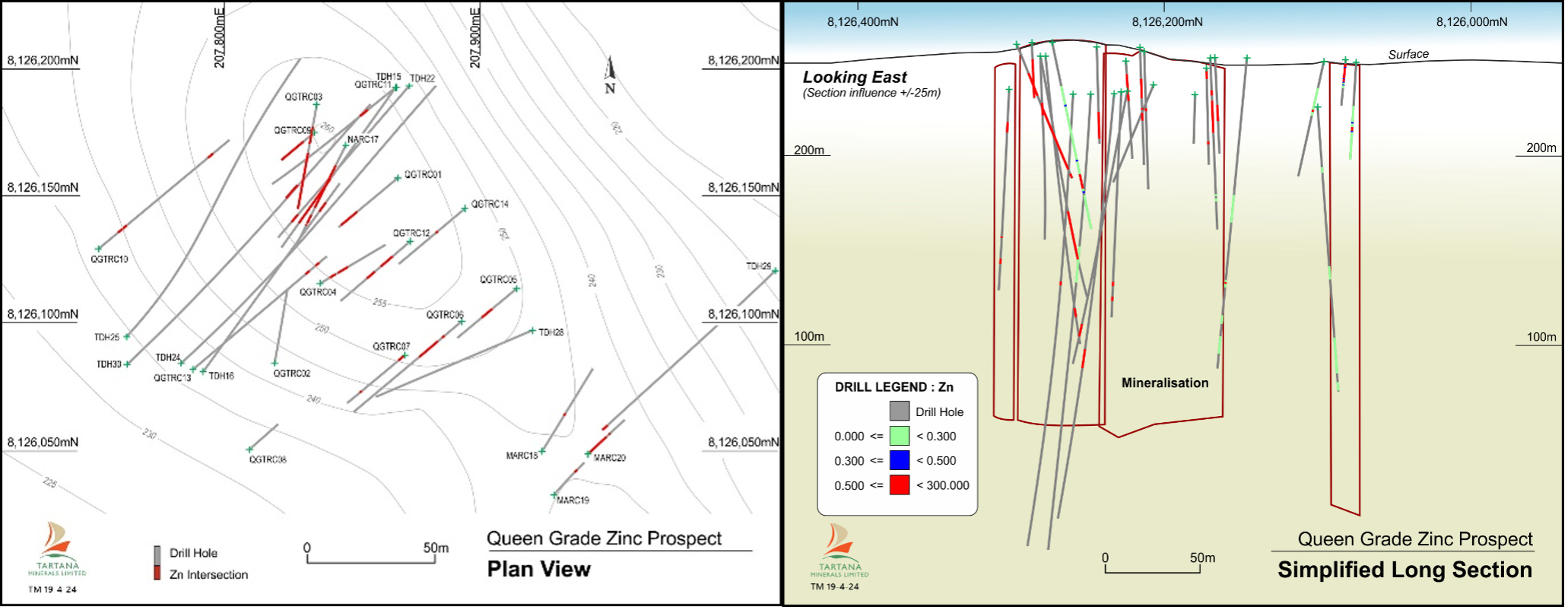

The mineralisation is hosted in sequence of steeply dipping limestones, andesite, bedded cherts and arkosic sandstones and with the gossanous material at surface representing he weathered sulphide rich skarn. The inferred mineral resource dimensions have been estimated within a 130m (strike) by 20m (width) by 160m (depth) volume.

Figure 2. 2(a) Queen Grade diamond drilling with the outcropping gossan in the foreground and the grey scar of the King Vol zinc mine in the background (owned by Aurora Metals Limited). 2(b). Part of the TDH24 downhole intersection of 12m at 10.7% Zn from 160.7m (See ASX announcement dated 21 October 2022).

Figure 2. 2(a) Queen Grade diamond drilling with the outcropping gossan in the foreground and the grey scar of the King Vol zinc mine in the background (owned by Aurora Metals Limited). 2(b). Part of the TDH24 downhole intersection of 12m at 10.7% Zn from 160.7m (See ASX announcement dated 21 October 2022).

Figure 3. 2(a) Plan view showing drill collars, hole traces and zinc mineralisation. 2(b) Long section with drill traces and zinc mineralisation. There is an interpreted fault ‘window’ between the main body of mineralisation and the southern body.

Figure 3. 2(a) Plan view showing drill collars, hole traces and zinc mineralisation. 2(b) Long section with drill traces and zinc mineralisation. There is an interpreted fault ‘window’ between the main body of mineralisation and the southern body.

As mentioned, zinc mineralisation extends to over 900 m depth at the neighbouring King Vol mine and it is expected that the Queen Grade zinc mineralisation is likely to continue to substantial depths beyond the 160 m depth used in the current mineral resource estimate. Figure 4 shows a cross section through the main zone and it is evident that the zinc sulphide mineralisation is relatively coherent and likely continue at depth.

Figure 4. Cross section through the main ore zone. Source: BMS

Figure 4. Cross section through the main ore zone. Source: BMS

Metallurgical Testwork

The Company has previously commissioned Core Resources Pty Ltd to conduct flotation testwork on a composite sample from Drill hole TDH 22. The testwork indicated high zinc recoveries of >98% to a concentrate grading 42% zinc with its initial rougher flotation testwork. The sample tested (from 5 m of TDH 22) assayed 16.1% Zn, 0.25% Cu and 0.57% Pb. Core Resources also report that the flotation kinetics were fast with recoveries achieved in 2 minutes in the laboratory tests at a primary grind of 80% passing 75 microns. Work is ongoing with regrinding and cleaning testwork along with analysis of zinc concentrates for any impurity elements.

Figure 5 is a photomicrograph of the Queen Grade zinc mineralisation from TDH22 with pyrrhotite (Fe1−xS (x = 0 to 0.2)) and chalcopyrite (CuFeS2) exsolutions with coarse grained sphalerite (ZnS) grains.

Figure 5 is a photomicrograph of the Queen Grade zinc mineralisation from TDH22 with pyrrhotite (Fe1−xS (x = 0 to 0.2)) and chalcopyrite (CuFeS2) exsolutions with coarse grained sphalerite (ZnS) grains.